Monday, December 8, 2008

NEWS From Abroad

I also get to see the downsides too. With the economic meltdown that is affecting us globally, it too is having a significant effect on hobby. More directly.. our manufacturers.

Asia is shedding jobs at an alarming rate. Factories (of all types) are closing down. Hundreds of thousands of people are unemployed. In regards to our RC hobby, it is being reported that over half of the manufacturers that once made our aircraft, parts and accessories are gone.

That's right... gone... busted... closed for good. And the bloodletting is still happening now. Some reports state that 3/4 of our hobby suppliers (this includes manufacturers, distributors and trading companies) may be gone in January/February.

Overall, in the short term, this will mean less choice for us, less selection, and perhaps some higher pricing.

In the long term, I feel that this event will be seen as a good shakeout that was a long time coming for our hobby. The cheap manufacturers of substandard products will be gone and give those who do survive and provide decent products at a decent price, with decent service, a bigger footprint of influence.

We do live in an interesting time for our hobby!

Using Loctite and How

To use or not to use.... that is the question....

To use or not to use.... that is the question....The answer is quite easy..... YES... use Loctite. But why....

My first experience in learning to use Loctite, came through practical exercises. A buddy of mine was flying his Quadra 35 in his beloved Fokker tri-plane. At about 1oo feet in front of a lot spectators the engine seemed to shift from its firewall location.

My buddy quickly shut the engine down and luckily landed the plane... though you really don't land Fokkers, you try to tip them over at low speed.....

The post mortem revealed that 3 of the engine mount bolts had vibrated off, and the fourth bolt was ready to depart.

Right there and then, it became clear that using Loctite was an imperative to good assembly practices.

Our gas engined planes experience a great amount of vibration. No matter how smooth you think your engine is performing at, vibration still exists, and it can be insiduous and it can be dangerous.

Anywhere you have metal to metal contact on your aircraft, a drop of Loctite is your best preventative measure. In conjunction with your usual and regular airframe checks, Loctite can save your day, by ensuring your connections stay and remain tight.

Is there somewhere that Loctite should NOT be used? Unfortunately... as much as like the product and use it religiously, there are areas NOT to put those insurance drops.

I do not apply Loctite to bolts that attach the propeller, especially if the props are made of wood. Wood props do compress and over time this may cause the bolts to loosen. By using Loctite the bolts will remain firmly seated even though the prop is moving within your bolts. No good....

Regular checks of Prop mounting bolts will ensure all is well and good..... Story time.

Prior to the above.... I did use Loctite on my prop bolts. LOTS of Loctite.... I used the good stuff too.. the RED Loctite... That prop was not moving for love or money....

I forgot that props break if you land poorly.... silly me..... Well it happened... My landing was not a graceful affair. No problem I thought... I will take the bolts off.. replace the prop and I will be flying in about 10 minutes.

Oh Oh....These prop bolts would not move... no how.. no way.... I broke the heads off 2 of them before declaring defeat. It took me hours .... plus applied heat that almost melted the washers and prop hub. Lesson learned well... so read on...

BUT WAIT... there is more.

If you go to your favorite hardware store, you will notice several grades (or colors) of Loctite. The natural choice is to use Loctite RED..... Resist this urge........ you must resist this urge....

Loctite is an excellent product that does exactly what it designed to do. Lock nuts and bolts in place. By using the wrong grade (color) can make your day a cussed filled affair.

The article on the ZRCGF web site link above, will provide you with all the information needed to make the right decision for the right product.

Using Loctite is a smart, preventative maintenance move for all of us modelers. A little bottle will last a LONG time, and it will save your model by working in the background to prevent loosened nuts and bolts from converting your flying time... into rebuilding time

Friday, November 28, 2008

Mounting Your Engine

Mounting an engine can be an exercise in futile frustration. Many of us struggle model to model with this issue. Is there a way to standardize a method and make things simpler?

Mounting an engine can be an exercise in futile frustration. Many of us struggle model to model with this issue. Is there a way to standardize a method and make things simpler?The answer is yes..... If you click on the link at the title bar. you will be taken to the ZRCGF web site, in our articles section.

The article was written by Pat Roy, and it takes into account years of experience in mounting engines. The exercise in mounting an engines does not need to be difficult OR expensive.

The engine mount does need to be sturdy, well thought out, and be adaptable to whatever engine we want to mount on the airframe. This article hits all the marks.

Follow the directions and you will have a mount that will serve you and your airframe well! The big plus is that this method can be used on most any airframe and any size plane.

Sunday, November 16, 2008

Ignition Systems and Interference

The First, Foremost and BIGGEST reason is Safety. The far distant second reason is the cost of replacing that beautiful bird. Oh, did I say mention SAFETY!!

RFI - Radio Frequency Interference - will be evident immediately if using a PPM receiver. Do not fly until you obtain excellent engine running range checks with a PPM receiver. Using a PCM receiver for initial range checks frequently masks some RF issues which can later push through the ability of a PCM receiver to filter them out. A crash comes almost immediately after that happens.

RFI - Radio Frequency Interference - will be evident immediately if using a PPM receiver. Do not fly until you obtain excellent engine running range checks with a PPM receiver. Using a PCM receiver for initial range checks frequently masks some RF issues which can later push through the ability of a PCM receiver to filter them out. A crash comes almost immediately after that happens.So the key is using a PPM receiver for those first critical system checks, not a PCM receiver. Engine off to establish a baseline, then engine running. You want no worse than a 10% difference between engine off and engine running range checks. Over 90 to 100' for a minimum distance, engine running. If you do everything right and have problems do not fly until EVERYTHING is working properly.

What about the 2.4 GHz frequencies that are quickly overtaking the 72 MHz market? You have probably heard that using the 2.4 GHz radios will eliminate you concerns. Right? In fact, it is absolutely incorrect to assume that is the case.

You keep believing that and you're sure to lose a plane. You won't be alone. Others have already gone before you with the same belief. Where the receiver is mounted is not nearly as critical as assuring that you don't have RF issues at all. I've been mounting radio components in close proximity to ignition systems for many years but what has permitted that to work every time is using good components in great condition and making all the checks to assure that any issues were eliminated prior to flight.

Using 2.4 GHz radio does not eliminate RFI, and the 2.4 GHz systems are still subject to various forms of jamming. If one has failed to achieve adequate range checks with the engine off and the engine running the loss of an aircraft is only a matter of time. Using 2.4 will not eliminate that problem, nor will PCM. Both only reduce the chance of a crash from ignition RFI, with 2.4 being better than 72 MHz PCM.

Never rule out anything when it comes to airplanes.

Click here - The ZRCGF website contains further information and checklists to use in finding these potentially unsafe RFI problems.

Saturday, November 15, 2008

Best Propellers to Use for RCGF Engines

So what is the best propeller to use - wood, carbon fiber, ? This is one of the more popular questions we get!

For any given plane and engine combination, there will be a propeller that will work best for the type of flying desired. 3d, IMAC, and scale flying each require a different type of propeller response, while each airframe engine combination exert their own influences. Rarely will you find two propellers exactly the same, and blade lengths, pitches, widths, tip shapes, and flexibility vary widely between brands and composition types. "Size" covers a lot of territory with propellers.

The word "typically" will be used quite a bit here because the descriptions that follow are not hard and fast rules, but a generalization.

Wood blades typically "spool" up faster because they are generally lighter than other types. The downside is they can be more flexible and therefore less

Carbon composite props are typically more rigid and have more consistent design and mold accuracy while frequently generating more rpm than a wood prop due to blade design and rigidity. Propeller weight increases when carbon composites are used.

Fiberglass composite propellers are typically very "mold accurate", but are slightly more flexible than carbon composite propellers. Propeller weight can be quite light for the size. Generally they are not as desirable for larger displa

cement engines. Fiberglass propellers are limited in available sizes because of safety concerns when used with large gas engines. Drilling fiberglass propeller hubs for multi bolt engine hubs can create safety issues for larger gassers.

cement engines. Fiberglass propellers are limited in available sizes because of safety concerns when used with large gas engines. Drilling fiberglass propeller hubs for multi bolt engine hubs can create safety issues for larger gassers.Unfortunately there is no "best" propeller type. Nor is there a "best" propeller that someone could ask for to provide the perfect performance for "their" particular plane. There will always be some variance due to fators induced by the person that assembled the plane. Final weights, engine choice, and desired flying style can make the prop you want or need differ from what works best for a person flying the same plane right next to you.

News from the Front

It has been a couple of weeks, and it only seems like hours!! Lots of things happening on the RCGF Engines front lines.

First off... Thanks to all the guys who are writing me about their RCGF engines, and the posititive experiences you are having. PLUS...the "things you would like to see" stuff in future engines is absolutely the best. Your ideas have all been heard - loud and clear... and the factory is examining ALL of them.

In fact let's talk about the current batch of improvements that are coming NOW.

1. Carburator orientation - When you get the engine, the carb is mounted with the low and high speed needles facing up - in the same direction as the cylinder. Many of our models require that the engines be installed inverted. Now the needles face downwards.

What modelers did not realize - and that is our fault for not promoting this - is the carby can be upbolted and a moved 180 degrees, so that it is facing up again. This is also great if you plan on using a Pitts style muffer.

Now here is the other part. The carburator can also be rotated 90 degrees in any direction. That means that now you can move the carby in 90 degree rotations to suit YOUR needs. Right now you will have drill and tap the holes if you wish to use the 90 degree rotation option. The factory will be drilling and tapping these holes now. The good thing is that the factory also makes the adapters.

2. Spark plugs - All engines can be retrofitted to use the CM-6 spark plug. These are 10mm

p

lugs. Our standard plugs are 14mm. Starting in December, we will be outfitting all the twins - 50cc Twin, 100cc and 150cc engines with the CM-6 plugs.

lugs. Our standard plugs are 14mm. Starting in December, we will be outfitting all the twins - 50cc Twin, 100cc and 150cc engines with the CM-6 plugs.The biggest advantage is the size of the plug. It is about 1/2 the size of the standard plug. This plug provide modelers with a smaller footprint. This will allow more "in the cowl" installations for models with narrower dimensions.

Upgrade kits are available, so any RCGF engine can take advantage of the smaller footprint size. Though not confirmed yet, we may be putting the CM-6 plugs into our 20cc engine as a standard . Stay tuned for lots more information on this.

The factory has really been working with us on getting these great updates out into your hands.

Wednesday, October 22, 2008

RCGF 65cc - In the Bushes

Ok... Here is something you don't see everday.... Look carefully...Tommie J. from Missouri sent this pic to me recently.

Tommie is hovering his 30% Yak (85" wingspan, 17 lbs or 7.7kg). He is not hovering above the bushes.. He is actually IN the bushes.

Tommie belongs in that special class of modelers - we all know that class - the fliers that are so confident of their skill and equipment, that any fear of loss of everything is not an issue...only the challenge of personal skills and ultimate accomplishment... Yup...and above is the proof.

I talked with Tommie and he loves putting himself in situation that extend his skills base. This particular pic was taken, he says, " To show the capability of the RCGF 65cc engine in an extreme circumstance".

I think that he has proven his point, and I am looking forward to his next challenge!

Tuesday, October 21, 2008

Clones, Copies, and Cheap Engine Knock-offs Oh My!

A while back, I got some emails from modelers who had noticed our engines on E-bay, and they were selling for less than the regular selling cost.

I answered all of the these fellas...

Yes it is interesting... There is a good reason....It looks like a RCGF Engine, but it is not.....

You will find me and all the distributors of the RCGF Engines repeating the same story. The RCGF Engine are the most copied, and cloned engines, bought through 3rd party companies and sold as their own by other engine sellers. Notice that I did not say manufacturers...

That is why RCGF Engines had to actually retool their engine line-up so that these other substandard designs won't be associated with the RCGF line. This was completed early this year, and these new engines are getting incredible reviews. As distributors of these engines we are really hesitant of talking these engines up. But it really is coming to a point that we need to differentiate ourselves from the lower tier crap manufacturers that are giving the quality engine manufacturers like RCGF, headaches.

Gas Engines that modelers think are manufactured by the company selling them, are in for a big surprise. Many of them are not. They are either contracted out, cloned, copied, forged or whatever you want to say. There was a seller that actually put a picture of the RCGF 150cc engine on their website and starting selling them as their own brand!!!

I see posts that have guys raving about the deals they got for an engine that should cost 100's more. To be fair, some of the deals are real and the buyer is the winner. But talking from personal experience, these deals few and far between. You know why....

The engines that are bought from unknown sellers are junk, made with substandard materials. The will run for a couple of hours or maybe even a season and then die. The seller has dozens of these cloned and copied engines and he is selling them one at a time.The posts on all the popular RC sites are full of these stories. So now a happy modeler becomes a pissed off consumer, looking for some kind of redress.

Good luck...go ahead and get some service for them....Go ahead..

Over the summer time I dealt with a number of modelers on these issues. It is frustrating and time consuming, but one service that I am pleased to do, so that I can educate them.

Here is the kicker on this too. Some of the sellers who were hawking the pseudo RCGF engines, actually gave the buyers the name and number of our Company, so that if any problems were experienced they could call us for immediate service. What a great scam....

One fella even sent me his engine. The box was a real RCGF box ( or one hell of a good copy!!), the instructions were written in Urdu (honestly!). The ignition system was blue colored.... (unknown to me or anyone else that I talked with). Now to the engine.

The engine was not even close to the look of our engine. Yes it had a cylinder head and a carburetor, but the spark plug did not fit the engine. The seller had even painted the muffler shiny black...

It took me hours of work to convince the buyer he had been had. Man... was he angry... I did feel for this guy. He eventually bought one of our legitimate ones.

Right now... with all the pro-active stuff that we have been doing on stemming the cloners and copiers, it seems that these guys have switched tactics. NOW, we are seeing cloned DL engines coming on line. I feel for the guys who think that they will be getting the deal, but instead getting the finger!

Monday, October 20, 2008

RCGF 100cc Engine - A Customers Experience

Hey All.

Just a brief introduction to this blog entry...

Pat Roy flies for a living. He is very in tune with the 2 Stroke Gas engines. He is also very particular. Last year, he bought one of our earlier generation 100cc engines, and did a personal review on it. The many items that he brought out that needed improvement to the 100cc engine, were in fact being done and for the better part were done.

The factory sent Pat, these parts, and Ralph Cunningham of RC Ignitions, installed the parts. Pat got the engine back, but because of work commitments could not get to the engine or his plane for the next couple of months. Well, judgement day came a few days ago. Below is Pat's blog report on the performance of the engine.

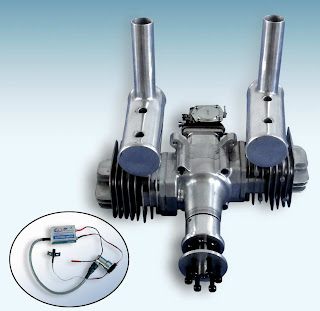

Pat Roy's Report on the RCGF 100cc Engine - First flight

Okay,

I just went out and ran the rear induction 100 twin again. 93 octane pump gas (with the CA ethanol blend of course), 50-1 Redline, 27-10 Menz prop, H-9 tach. The reason for the 93 octane was to help boost the octane level of the little bit of old 87 octane gas that had sat in the can for the past three months. This is the original engine that helped provide data for the improved versions now on the market. You guys are definitely getting your money's worth!!

I'm not going to tell what the tach readings were. Nobody would believe me, but I'm pretty sure I'm going to need a 28" prop!

Or a lot better tach. Or both.

Or a lot better tach. Or both.I did make a small change in it before mounting since I like to use only one type of ignition instead of a bunch of different ones. I got rid of the 14mm NGK BMR7A's and installed some 10mm reducer inserts so I could use NGK CM-6 plugs. Doing the same for my single cylinder engines as well just to make life a little easier when it comes to parts replacements and interchangability. I removed the RC Exl ignition and used a real life CH Syncrospark ignition with the machined 10mm plug caps. The change raised the height of the plugs inside the cylinder a bit. I don't know if that provided more cylinder volume to admit more of a combustable mix or slightly lowered compression permitting a little more rpm, or both, or what, but it really runs GOOD!

I have another RCGF rear induction 100 coming that incorporates all the latest improvements for comparisons. If it runs as well or better as this one does I'll be in engine heaven

If anyone wants to try the plug change the reducers can be obtained from both CH and RC Ignitions. There's only one place to get a true Syncrospark. CH is still the king of the hill

Ralph C.,

I don't know what all you did to this thing but whatever they were, they worked!

I finally flew my early version RCGF 100 today. It's the one that has been upgraded with some of the mods that went into the new and improved version. Not all, only a few. Here's the skinny.

35% Edge, 24 lbs. 4 oz. dry. Since it was first flights I added 8 ounces of ballast to the nose to be a bit forward on the C/G for stability during the shake down flight. So plane at 24 lbs., 12 ounces. Add in a pound and a half for a full 32 ounce tank of gas to the take off weight. So make it a round number of 26 pounds.

Field elevation roughly 1,200 msl, 75 degrees f, 30-35% humidity. No wind. Same gas and prop as before. Engine not even close to broken in yet with about 60 ounces of gas through it.

Take off was about 15-20 feet with unlimited vertical as near as I could tell. Second take off in about 10' since I wasn't as nervous as the first flight. Smooth running at all rpm ranges. None of that DA blubbering to be found anywhere. Pulling into a hover it didn't seem to require much throttle to keep it there, generally well below 1/2 stick. I don't use a throttle curve. The big surprise was when I goosed the throttle a little bit in the hover. It was like "Lets Go!!" The plane instantly jumped upwards!! Altavillan and RTK may come in to provide some support of that statement. I never had to go to full throttle to have a fast and solid pull out of the hover. Overall it's a very strong little engine that you get to obtain for less money that it would cost you for one of the "majors".

If I had any complaints at all it would be due to needing to do an idle up after the take off. Since it's real low time a low rpm idle is unreliable, causing for engine stoppage if you've been flying around at low throttle positions for awhile. You don't need to be past 1/2 stick to fly a 26 pound, 2,000 sq. inch wing area plane in any attitude. Matter of fact, flying at high rates, 3d deflections, I spent most of the time at 1/3 throttle stick or less with a little bump once in a while to pull through a maneuver. I think that as the engine breaks in a bit more this issue will take care of itself. If it doesn't, so what, I know what she likes to keep going and moving the throttle trim 3 clicks either way to make her happy is not going to be an issue or inconvenience.

Good engine, plenty of power, smooth running, and a low price. And all that with the early version that's not even close to the standards of the new one. I'm quite pleased with the way this has all turned out. Enough so that I have another one coming for my 41% Giles. This one is all the power I ned and more for the 35% Edge

Wednesday, October 15, 2008

RCGF 45cc Engine and the Aeroworks Extra 35

I received an email from Jake Ruddy recently. He is in the process of writing a review of the Aeroworks Extra 35 , for RCU. And additionally he is also looking for an engine for the review.

He is considering the Evolution 35 or their new 40cc engine. That said.... he is also looking at the RCGF 45cc engine.

He asked me, what my thoughts were about the our 45cc engine. It took me a couple of hours to compose an answer that was unbiased. It is interesting to talk about an engine one knows though.

Here is what I wrote to Jake...

Hey Jake!!

Thanks for writing... The Aeroworks Extra 35 is an awesome plane. I saw a couple of them flying this summer. The pilots had nothing but good things to say about the kit. The RCGF 45cc is an excellent choice for the plane. Now for the details.

The current RCGF 45cc is our current and newest release. The big difference is the rear induction. The original 45cc had a side induction system. I have and use the older engine in my ACE Big Bingo. It has an all up weight of 19 pounds - yeah it is heavy. However, that is how Ace designed this bomb shelter back then.

You know Jake, you can read all the engine specs you want. They really don't mean anything outside of the size of the engine and cost. Here is why... Most manufactures state their HP ratings. However, instead of HP, they are actually stating Brake horse power. The difference is that Brake Horse power is what the engine will produce when there is no load on it. Few manufacturers will put out the true HP because there are so many circumstances that will affect their readings.

Also, along the same lines.. many of the gas 2 strokers are converted industrial engines. Industrial 2 strokers are designed to produce their max hp at high rpms. In our hobby that is not necessary a good thing. Our props and the physics behind them produce their maximum thrust when the propellers reach from between 70-80% speed of sound. After that, there is no gain in thrust, no matter how fast that prop is spinning.So what I am saying is that though hp and rpm are interesting indicators they have no real value in determining what an engine can do. The only way to compare apples to apples is with a dynometer.

That is expensive... (we are actually building one though... once done we are giving it to an independent tester who is well known in the RC world, and he will conduct the tests for our engines and all others that want to be tested. No bias, which is what is wanted).

Ok... so no dynometer, but there is another way. And a lot cheaper... Simply go into Walmart and or any other discount store and by a digital fish scale...

Carefully put cord around the wings of your airplane, then attach the scale. Take the reading. Will it be precise? It will be close enough. In the air the engine will unload further and provide more thrust, but this will give you a great indicator. Plus you can use this for ANY aircraft.

Pounds of thrust reading. Simple and straight forward.

Ok...Prior to the becoming the distributor of RCGF Engines, I bought a whack of them for trials. Many I gave away to friends for their opinions, some I sold at cost to customers, and some I kept. I kept three engines the 45cc 50cc and the 65cc...

I did the above thrust test to them. In fact...I did not believe my initial results... I threw away the scale and bought a new one immediately (on sale at Walmart - $14.69). I did the test again. Hmm results were the same. I called a friend and he brought his scale over. Similar.

The old 45cc was pulling 22 pound - 23 pounds of thrust. It was turning a 21/8 TZB at 7400 rpm. The old style 50cc was pulling 25 pounds, and the 65cc was pulling 34 pounds of thrust. I became the RCGF distributor right after these tests.

OK that was the older style.. Enough history.. lets talk about the new ones. The new models were introduced with little fanfare in May/June of this year and we got quantities of all of them shortly thereafter.The 45cc had the new rear induction system. With a more consistent fuel delivery system from the carb to the cylinder, the expectation was for at least the same amount of hp.The fish scale testing showed a 24-25 thrust now. Same propeller used. In fact, I believe that if I went to the 22/8 or 22/10 the thrust would be higher.

To give you perspective - the new 50cc gained - it is showing 28 pounds of thrust. We are just getting quantities of the new 62cc. Though not tested here, the factory is stating 37 pounds of thrust.

Perspectives about the RCGF 45cc engine.

1. Thrust output is the highest of any 45cc size engine I have seen.

2. The crankshaft has bearing not bushings

3. Rear induction - this provides more options for mounting the engine without cutting the sides of a cowling for access to the carb etc.

3a. Rear inductions also have the advantage of minimizing any gas spitting. Side induction and front inductions do have this problem of gas spitting out the carb.

4. The RCGF 45cc was designed for aero applications. It is not a converted design of an industrial engine.

5. Crankshaft - hardened steel. Ralph Cunningham of RC Ignition calls the RCGF cranks among the best he has ever seen.

6. The entire RCGF line up uses the RCEXL ignition system. Bulletproof and proven design.

7. The engine is light weight and powerful. It is actually lighter than the Evolution 40 (51.2 oz) and RCGF 45cc - (48.5 oz).

8. Mounting is by rear engine lugs. It allows for customized mounting, using standoffs or whatever the modeler feels comfortable doing.

9. Easy starting.

10. Walbro Carb

11. Cost is 269.99 - The Evolution cost is $500... You could almost by two.

12. Parts cost is much lower - RCEXL ignition cost is about $70. Evolution is almost $200.

13. Engine break in is simple - 20 minutes on the plane to familiarize yourself with the engine. Use 32:1 oil/gas for several hours or gallons. Then switch to a high quality synthetic. I recommend BelRay at 50:1. It will give you another couple hundred rpm once the break in process is done.

It is not my intent to compare the two engines in a side to side, outside of costs or weights. The Evolution is an good engine with a decent design. In my mind it is just WAY too expensive.

We have been flying the RCGF Engines for a couple of months now and the reliability and consistency of the motor is excellent. Reviews have been excellent on the entire engine lineup.

Sunday, October 12, 2008

Engine Factory or Trading Company?

This is really apparent when the fellas buy the engines from E-Bay and similar sites. So now what........ well your options are few unfortunately. You can contact the seller... good luck... because by now they have changed names, and emails. They have your money and you have the engine, so their responsibility it done.

You can contact the factory directly.. if you know where it is. Again, good luck, because some of them will not sell you parts. They may not even have the parts you need.

It really is a buyer beware world when you buy an engine from an overseas supplier. Some fella's get good engines and they are happy with them... Congratulations.. Others spend big bucks and end up with engines that last several hours and then fall apart.

What really riles a lot of the honest distributors of RC gas engines (I am not just talking the RCGF guys, but many of the others too) is that some of the faux pas sellers masquerade as factory dealers, sell cloned, counterfeit, crashed engines to unsuspecting and trusting modelers. The modelers get these engine, find out they do have junk, and they go to the legitimate sources looking for restitution.

Of course there is none, because all of the legitimate sellers use data bases and will only support their customers. Bad feelings result, and a legitimate supplier has lost a potential long term customer through no fault of their own.

RCGF distributors have dealt with numerous cases of this over the last 8 months. RCGF Engines have been cloned and copied and sold through various channels. The sellers actually tell the customer to go to us for service. We have received engines that are in the RCGF shipping box, and even have the same instruction manual. The engine though is not even close. It doesn't look like ours, or even have any similar components. The seller uses legitimate RCGF Engine pictures and delivers someone elses engine.

Now we have to tell the fella who spent good money on an engine that we cannot support it. It makes for a crappy afternoon.

Buy from legitimate sources. Sure it may cost a few bucks more. But consider that really cheap insurance.

RCGF Engines

Welcome to the RCGF Engines Blog site. Here, I will try to provide you with updates, information, hints, secrets, rumors and other cool stuff that ya absolutely need to know. And of course the stuff that is fun to know more about.

About RCGF Engines -The Story

RCGF Engines - the full official name - Zhejiang RCGF Model & Engine - was started in 2002 with engine manufacturing and assembly starting in 2003. Yes... they are a Chinese company.

When they started out, their engine line up were basically converted industrial engines. Actually their first efforts were pretty good. A lot better than some of the current engines out there today!

As they garnered more experience in aero design, they started coming into their own with engines that were specifically designed for flying. The industrial engine "look" was fast disappearing.

Today, when you see their line up of engines, RCGF has the most extensive line up of engines of any gas aero 2 strokers out there. And more are coming... believe me.. I am as amazed as anyone when they are telling me their outlook of what they have planned out. Interested... read on...